About Rico

Specializing in the research and development, design, production, manufacturing, and use of forged steel cold roll technical services, as well as the production of spare parts for rolling mills

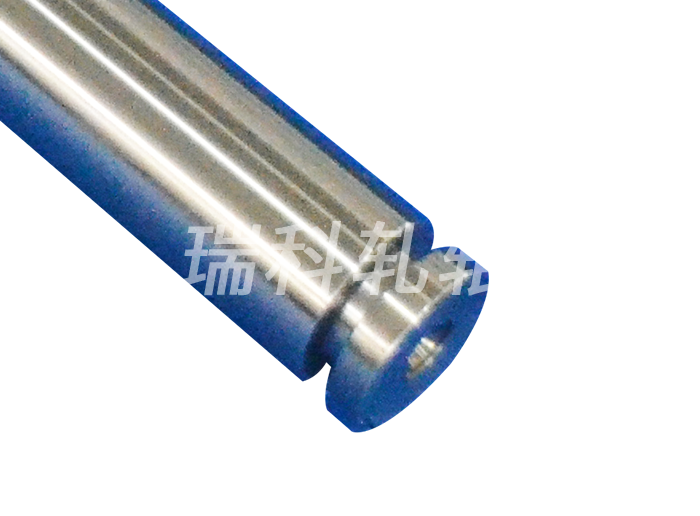

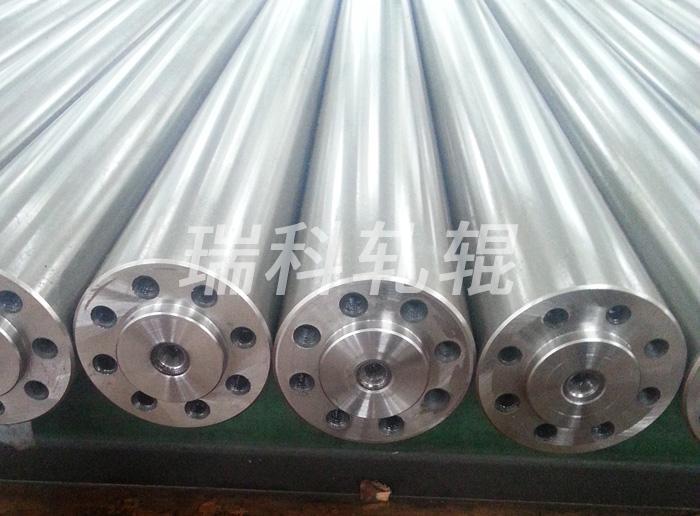

Changzhou Ruike Precision Roll Co., Ltd. is a private enterprise with a history of more than 20 years. The company specializes in the research and development, design, production, manufacturing, and use of technical services for forged steel cold rolls, as well as the production of spare parts for rolling mills. With the continuous development of new material technology and the introduction of heat treatment technology from Japan, a series of high-performance rollers have been developed, and various materials such as Cr12MoVCo, D2, 5H12, M2, M42, M1, and M7 have been formed.

Industry production experience

Enterprise floor area

Key partners

Annual production of various types of rollers and spare parts

Product Center

Specializing in the research and development, design, production, manufacturing, and use of forged steel cold roll technical services, as well as the production of spare parts for rolling mills

News Center

Specializing in the research and development, design, production, manufacturing, and use of forged steel cold roll technical services, as well as the production of spare parts for rolling mills

2023/03/01

Application of Simulation Technology in Roll Development

The purpose of simulation application is to improve process technology methods, improve product quality, master the process of cold bending molding, reduce roll repair and modification design, and save production debugging costs. The simulation of cold bending forming process cannot be separated from the experience of roller designers and the installation and debugging process of forming equipment. The simulation without experience and process knowledge of cold bending forming process is meaningless and can have serious consequences in practical applications.

2023/03/01

An improved roller cooling and gap lubrication device, an improved roller cooling and gap lubrication device, belongs to the technical field of rolling mills. Used to solve the use defects of existing devices such as uneven lubricating oil film and easy mixing with residual cooling water. The composition includes upper and lower water cutting plates located at the entrance of the roller gap, c

Mobile Website

CHANGZHOU RICO PRECISION ROLL CO.LTD.

Address:No. 28, Shangde Road, Xinbei District, Changzhou City, Jiangsu Province

Contact:Mr.zhou 13585326600

Tel:0086-0519-8560-0297

Fax:0086-0519-8595-8689

Postcode:213125

E-mail:ruikezhagun@czrico.com

Copyright © 2023 CHANGZHOU RICO PRECISION ROLL CO.LTD.All Rights Reserved. IPV6