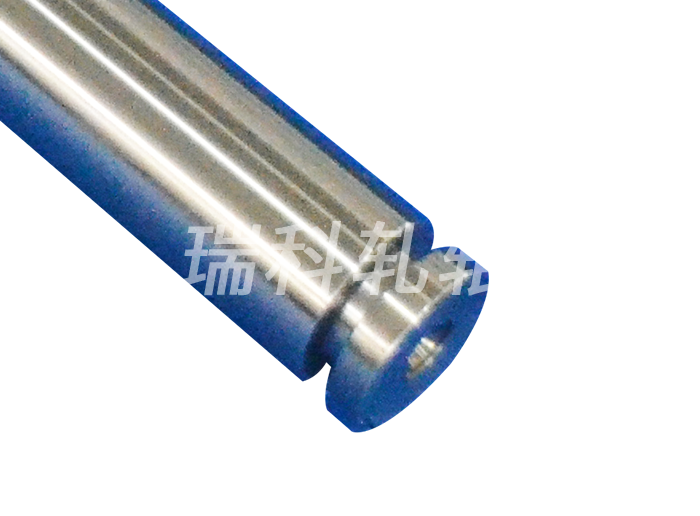

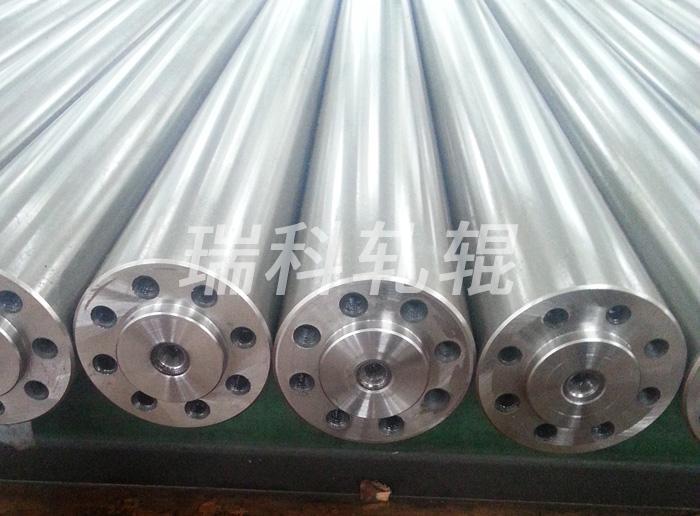

Twenty roller two intermediate non drive

Widely used: The second intermediate non driving roller of a twenty high mill is widely used for precision rolling of various types of plates and strips, such as stainless steel, silicon steel, copper, titanium, and high carbon steel, with materials of 5H12

Category:

Product Description

The material of intermediate roll is required to have high thermal shock resistance. The service life of roller is shortened because of peeling and crack caused by cold hardening of roller surface due to high thermal shock resistance of intermediate roll, which is one of the most common problems of intermediate roll. Our company endeavors to design the intermediate roll according to the requisite properties of intermediate roll through the study on material smelting and forging, material selection and special heat treatment technology for the purpose of preventing peeling and crack caused by high thermal shock resistance.

Taking H12 as an example, it has high pressure resistance. The microscopic structure generated by the special heat treatment technology can strengthen tenacity and pressure resistance.

In addition, the intermediate roll made from the latest R8 material and special heat treatment technology has higher pressure resistance and no peeling or crack. The result of compression test is higher than most of intermediate rolls, and the service life is more than two times the common intermediate roll.

| Applicable Roller | Material | Hardness | Material Properties |

|---|---|---|---|

| Intermediate roll | D2(12%Cr) | 58-62 HRC | Peeling or crack is caused by higher hardness of roller due to high thermal shock resistance. |

| Intermediate roll | H12 A8(modified)5%Cr | 58-62HRC | Peeling or crack is caused by higher hardness of roller due to high thermal shock resistance. |

keyword:

Senzimir roller | Multi roller mill roller | Four and six roller mill roller | Metallurgical spare parts

Related Products

Product Inquiry

Mobile Website

CHANGZHOU RICO PRECISION ROLL CO.LTD.

Address:No. 28, Shangde Road, Xinbei District, Changzhou City, Jiangsu Province

Contact:Mr.zhou 13585326600

Tel:0086-0519-8560-0297

Fax:0086-0519-8595-8689

Postcode:213125

E-mail:ruikezhagun@czrico.com

Copyright © 2023 CHANGZHOU RICO PRECISION ROLL CO.LTD.All Rights Reserved. IPV6